Student projects - Development of adapting dynamic models for large-scale heat pump systems

Vælg side

Photo: Plant owned by CTR, HOFOR and VEKS. Funded by EUDP.

Project 1

Download

Please, send your application marked "Project 1" via the application form on our website.

Background and Motivation

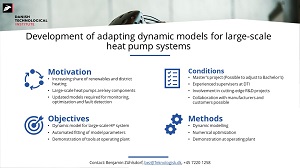

Denmark is a frontrunner in the share of renewables and district heating. Large-scale heat pumps are a key-component in this arrangement and imply the potential to facilitate a further uptake of both technologies. Heat pumps can supply heat to the district heating network in a sustainable matter, while implying the possibility to stabilize the electricity grid. In this context, the importance of heat pumps is increasing, and it becomes even more crucial that the systems are operating stable and most optimally.

A great potential to monitor the system and ensure optimal operation is ascribed to so called digital twins. A digital twin is a numerical model that is continuously adapting itself to the current status of the system.

Objectives

The suggested project aims at developing an adapting dynamic model for large scale heat pump systems, which can be used for further detailed system analyses.

The project comprises the following objectives:

- Development of dynamic model for large-scale heat pump system

- Analysis of dependencies between measurements and model parameters

- Development of automated parameter fitting to adjust the model parameters

- Demonstration of the developed tools using measurements from the operating plant

Methods

The specific methods to be applied during the project will be determined in agreement with the student.

The idea is, however, to use the following methods:

- The dynamic modelling should be conducted in the Modelica language, using Dymola and the commercially available TIL library

- The automated parameter fitting should be conducted in Python

The project will be based on existing and operating plants and may be conducted in collaboration with the manufacturer and the operator.

Supervision and Formalities

The project is designed for a master project, but may be adjusted to a bachelor project. The project can be carried out at or in collaboration with the center for Refrigeration and Heat Pump Technology in the division for Energy and Climate in Aarhus.

Benjamin Zühlsdorf will be supervising the project at Danish Technological Institute. Feel free to contact him if you are interested and want to hear more about the project.

Please, send your application marked "Project 1" via the application form on our website.